Feature Interview with Mike Morrison

November, 2010

How did Bailey & Izett come to be formed?

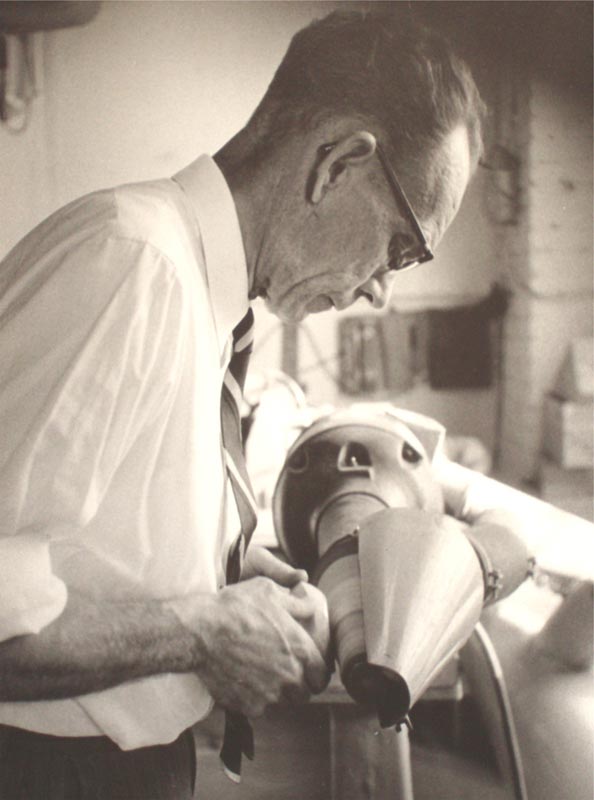

Bailey & Izett, Inc. was formed as a result of the closing of the Wholesale Golf Division of Wanamaker’s department store in 1940. Wanamaker’s retained its Retail Golf Division, but dropped the Wholesale Division. At that time, Wilfred Bailey was the manager of the Wholesale Golf Division and George M. Izett was the primary source for the wooden woods that they were selling. When the news of the discontinuance was presented, Wilfred Bailey knew that there was an ongoing business opportunity, but he needed to have a source for the manufacture of the clubs – Bailey was not a clubmaker. Mr. Bailey contacted George M. Izett, father of current partner, George G. Izett, and asked if he would consider a business partnership to continue the business that had been done by the Wholesale Division. George M. Izett had been initially trained as a clubmaker by Ben Sayers in Gullane, Scotland, had come over to the states to work for Ben’s brother, George Sayers, at the then Merion Cricket Club golf course (later in the 1940’s to separate and become know as Merion Golf Club), became a PGA Pro and was at the time of Mr. Bailey’s proposal the head PGA Pro at Seaview Golf Club in New Jersey. Due to George M. Izett’s love of clubmaking, he decided to enter into a business venture with Wilfred Bailey and form Bailey & Izett, Inc. in 1941. The business was originally just a continuation of the Wanamaker’s concept – wholesale sales to golf professionals and located in downtown Philadelphia on Chestnut Street. In 1946 George G. Izett was instrumental in purchasing the current building at 2538 Haverford Road in Ardmore, PA, partly for the need for extra space and partly due to its proximity to the Izett family home in Merion, about 5 minutes away. With the new facility and the growing brand awareness of clubs that George M. Izett made, the building was changed to allow for retail clientele and has been open to the general public ever since.

Any favorite stories having made clubs for Jones, Snead, Eisenhower, and JFK?

George M. Izett was the Primary Assistant and clubmaker under George Sayers when he repaired overnight the chipped face of Bobby Jones driver after the first day of competition at the 1930 U.S. Amateur, which Mr. Jones then went on to win the tournament and retire from competitive golf with the Grand Slam. Later as the business obtained national prominence due to George G. Izett’s abilities as a clubmaker, George M. Izett was quite young and just remembers that it wasn’t unusual to get calls from all over the U.S. for particular models of the Izett line due to exposure to one of our drivers from a current customer. A prominent local customer and close friend of George M. Izett, Frank Sullivan, Esq., led to the introduction to Bob Hope and other Hollywood entertainers (including a set made for Jackie Gleason where all of the clubs with the exception of the sand wedge where wooden woods – predecessors to hybrids). Production of clubs for President Eisenhower and then President Kennedy was a result of the prominence our clubs had obtained in that time before advertising and marketing took a dominant hold in the industry.Sam Snead’s Izett driver was sold to him by his close friend Henry Picard, head pro at the Hershey Country Club. Henry let him hit one of his stock drivers in an effort to find a driver that would cure the significant hook that Snead was experiencing with his driver. The Izett driver did the trick and stayed in Sam Snead’s hands for most of his distinguished career.

What clubs have come out that change the way the game is played? Sarazen and his sand wedge is but one such example.

In the recent history of the game the most significant changes have been the graphite shaft – primarily for its effect on the setup of the driver, allowing the longer 45†and more length that is played as standard today versus the 43†standard length steel shafted persimmon driver common even in the late 1970s. The use of Titanium in driver clubheads also has had its impact on the size of today’s driver heads and their high moment of inertia design – less shot dispersion as the center of the face is missed at impact. Hybrids are a re-introduction of a design that existed in the wooden wood days, but did not take like it has recently. Hybrids are not necessarily a better option, but they are an additional option that can provide a benefit not available for a particular golfer from a long iron or a lofted fairway wood.

What are the great innovations in club making in the past twenty years?

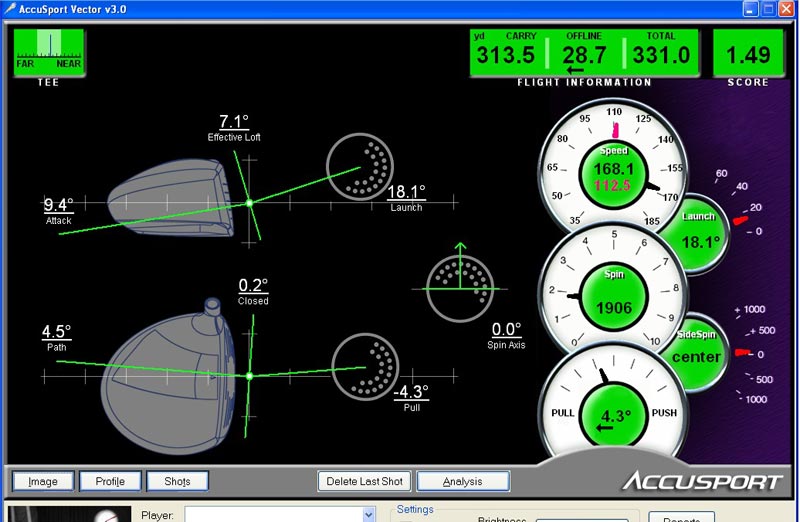

The availability of launch monitor technology which is a result of the reducing size of computers, the improvement in camera optics and the impressive complexity of software. This tool allows an understanding of ballistics to a level not ever before possible. Especially in the driver fitting process, the ability to actually understand the characteristics of the ball flight and what changes will improve the flight without any change required from the golfer is very significant. Also the general miniaturization of measuring devices has allowed very complex load measuring technology to be available for analysis of the golf swing with accurate determination of optimal shaft flex for irons and woods.

What is the most important component in a club?

As far as our experience shows us, there is not just one component that is important in a golf club. I say this because we have analyzed customer’s clubs that fit properly for length and flex yet were very poorly balanced. Fixing the balance provide a transformation in the playability of the club – per the customer’s reaction. When the flex has been significantly different than optimal with other variables – balance and length – being correct, the correction of the incorrect flex again leads to a significant improvement in the playability of the golf club – again by customer response. Same is true if length [primarily in the irons] is the only variable that was not optimal.

Does shaft technology change faster than club head technology?

Shaft technology is definitely changing faster than clubhead technology. Basically this year’s clubheads are just a remake of prior years (both for irons and woods) with the only factor changing being the actual loft of clubs (irons are being de-lofted and drivers are being marked as 9.5° when they actually have some 11° + of measured loft)*. Despite the rapid change and introduction of new shafts annually, time is needed to see which introductions are truly valid or have the staying power to find a long-term place in the market – example: True Temper BiMatrix & EPIC, Hybrex, STULZ, etc. Some new shafts provide a feel, design and performance or launch and spin combination not otherwise available. Examples are: Aerotech Steelfiber – a graphite iron, hybrid or fairway wood shaft that provides graphite distance and vibration while retaining steel-like distance control due to a filament of steel wound down the outside skin of the shaft. OBAN shafts – a new line of driver, fairway and hybrid shaft with a distinctive feel and spin performance. ACCRA Dymatch – a new line of driver, fairway and hybrid shafts designed in tandem to provide the type of consistent feel from driver to fairway to hybrid seen to be preferred on the PGA Tour. There also have been solid new shaft introductions by MATRIX, FUJIKURA and Mitsubishi Rayon.

* – Irons are de-lofted to “prove†that they go further due to “technological improvements†– a purposeful misleading of the golfing public and drivers are more lofted than marked due to the combination of today’s lower spinning ball and titanium driver head combination requiring greater launch angle at impact to provide optimal distance and golfers won’t buy a 11° driver, let alone a 13° driver.

How important is custom club fitting for the 12 handicap golfer?

Regardless of handicap level, custom fitting provides improvement – however I am describing the results that we see with our customer base. If another “custom clubmaker†does not utilize the methods that we employ, then I can not speak to those results.** A 12 handicap or above are customers that seem to benefit the most from custom fitting. They do not yet have the skill set to make clubs that do not fit play anyway due to their athletic skill in manipulating the club minutely at impact. The 12 handicap or above all too often does not play or practice frequently enough to easily adapt to clubs that are of 1) different flexes and often 2) significantly incorrect flex in the same set of clubs. This leads to more inconsistent shot characteristics than are related to the skills of the golfer.

** One of the problems in our industry – there is no ranking system for custom clubmakers. There are many custom clubmakers that I would not recommend, even though they are our peers. There are some PGA Pros who have good fitting skills, but they are hampered by not being able to control the quality of the final product and are not even aware that this is an issue. Neither is the general golfing public. Our industry has NO standard for flex. Thus no matter how a golf shaft is made it can be marked for flex however the manufacturer chooses with no regard for all of the other shafts made in the market or even the other shafts made by that same manufacturer. This is one of the many things that leads to a chaos in the final specifications of the golf club produced today. We see it to be very significant from customer feedback how a well fit club performs versus the more common mis-fit club (which was possibly delivered subsequent to a prior incomplete and incorrect “custom fitting†or just from purchasing used or as a stock setup).

Do you find it odd that the average USGA handicap hasn’t come down over the past three decades, given all the improvements in technology?

No, I do not find it odd, since fitting is still a widely varied process with probably more error due to today’s fitting cart concepts. Beyond this, golf remains a very complex and mental game. We, as golfers, still get in our own way mentally on the golf course.

Is there any evidence that cavity back irons help a golfer with a less than 5 handicap versus blade irons?

I have not ever read a sufficiently controlled test that would give details on the exact extent of the impact of moment of inertia or lack thereof in the design of iron clubheads. The test would need to be done with a mechanical “Iron Byronâ€, the clubs would need to purposefully set up to be exactly the same in all specifications and then a very exact measurement of results from variance form on-center impact mapped to show the significance of the different head designs. To my knowledge this has not ever been done. The perception in the golfer’s mind is obviously a factor in this decision process and is exacerbated by the heavily advertised fear of having a clubhead that is not forgiving enough. Proven by the description of a higher moment of inertia club as a “game improvement†club.

To whom do you recommend blade irons?

We sell blade style irons to whoever prefers the look of the head at address and has a significant preference for feel at impact. This tends to be something that lower handicap players prefer, but we have some (a fairly small number) who are higher handicap golfers who play and prefer blade style irons.

Do people still appreciate craftsmanship in club making as they did in George M. Izett’s day?

Craftsmanship is not as evident as it was in the wooden wood days. From the response of our customers, though, I do believe there is an appreciation for what occurs when craftsmanship is used to make a consistent playing set of golf clubs, driver through wedges.

From a club maker’s standpoint, what do the next ten years look like?

The next ten years will hold unexpected developments – history shows us that this will be the case. However, the need for being properly fit will never loose its value. Thus we will analyze and incorporate the changes to continue to provide well fit clubs that play to the maximum benefit of the golfer.

Other than the putter, what is the single most important club in a golfer’s bag?

The driver is the other most important club. It is the longest and hardest to control. It is the one that is most sensitive to correct or incorrect ballistics. It is also the predominant club, other than the putter, that flavors the rest of the play for that day. If the golfer can’t keep the driver in play, then he is going to have a long and frustrating day.

What mistakes do most golfers make in assembling a set of clubs?

Most golfers want to quantify clubs in a spreadsheet method – do all of the lofts follow sequentially. However, it should be based on what clubs perform optimally for each required distance. A club should not be included in a set of clubs that is not effectively used, despite who has stated that “no golfer should be without oneâ€. A prime example if this is the 60° wedge. A fair number of our customers do not use this club effectively on the course but feel they are supposed to have it in the set. Thus, some other more effective club may be possible, but not used. This is not what we recommend. Set up the bag to play the most consistently and to cover all of the distances that are necessary during normal play.

I can personally attest to the fact that your deep face 3 wood and 60 degree wedge make the East Course at Merion an easier course to play. In addition, many Merion members still use your persimmon Grasshopper Ralyor to tackle the rough. Do you believe in customizing a set to a particular course?

ABSOLUTELY!! We love the concept of 20 clubs for a 14 club bag. But seriously, we have many customers who will alternate clubs in and out of the bag due to the normal shots encountered on a particular course, the length of the course layout and the difficulty of the rough on a particular course.

What club in a bag can a club fitter have the most positive effect on in improving someone’s overall game? Is it adjusting the lie/loft/bounce in a wedge or something else?

The most important club in the bag to fit correctly and to have a very determined philosophy of performing well with is the putter. We fit the putter for length, lie, balance and grip, but we also examine the philosophy of how to putt – pendulum or toss the ball. The improvements in a driver are the second most significant impact. We do adjust wedges characteristics by grinding different flange width, bounce and heel relief. However, there are a fair number of our customer base who are not aware of the differences or don’t value the concept of changing these features.

The End